1. Was bedeutet Kohlenstoff-Stahl, Werkzeug-Stahl, Carbon-Stahl, usw.?

Stahl für Messerklingen besteht in seiner reinsten Form möglichst nur aus Eisen und 0,6 - 1,4% Kohlenstoff. In dieser reinen Form ist das Gefüge im Stahl sehr feinkörnig und die Klingen können eine enorme Schärfe und Härte von bis zu 67HRC (Rockwell) erreichen. Hierbei ist der Stahl aber sehr empfindlich und die Klinge ist hart wie Glas. Um eine harte, aber gleichzeitig flexible und robuste Klinge zu erhalten, muss der Stahl nochmals bei niedriger Temperatur angelassen werden. Dadurch geht etwas Härte verloren und die Klinge hat danach in der Regel 60-63 HRC Rockwell.

Stahl für Messerklingen besteht in seiner reinsten Form möglichst nur aus Eisen und 0,6 - 1,4% Kohlenstoff. In dieser reinen Form ist das Gefüge im Stahl sehr feinkörnig und die Klingen können eine enorme Schärfe und Härte von bis zu 67HRC (Rockwell) erreichen. Hierbei ist der Stahl aber sehr empfindlich und die Klinge ist hart wie Glas. Um eine harte, aber gleichzeitig flexible und robuste Klinge zu erhalten, muss der Stahl nochmals bei niedriger Temperatur angelassen werden. Dadurch geht etwas Härte verloren und die Klinge hat danach in der Regel 60-63 HRC Rockwell.

Carbon-Stahl (Kohlenstoffstahl) wird schon seit Jahrhunderten bei z.B. Japanischen Schwertklingen wie dem "Katana" oder auch bei Rasiermessern eingesetzt und wird unter dem Namen Tamahagane verkauft. (Ähnlich dem 1.1274-C100 in unserem Shop)

Auch heute noch übertrifft eine Messerklinge aus Kohlenstoff-Stahl jeden "rostfreien" Stahl in der maximal erreichbaren Schärfe und Schnitthaltigkeit.

Für tiefergehende Informationen empfehle ich das Buch "Messerklingen und Stahl" von Roman Landes.

2. Was genau bedeutet "nicht rostfrei" bei Messern und Klingen aus "Carbon-Stahl"?

Messerstahl besteht (wie unter 1. beschrieben) möglichst nur aus Eisen und Kohlenstoff, um ein sehr feines Stahlgefüge und somit eine rasiermesserscharfe und schnitthaltige Klinge zu ermöglichen.

Diese Kombination ist aber ungeschützt gegenüber Säuren und Feuchtigkeit und die Messer sollten nach Gebrauch unter Wasser abgespült und anschließend abgetrocknet werden. Ein Merkmal von Carbonstahl ist, dass sich eine graue Verfärbung auf der Klinge bildet. Die sogenannte "Patina" ist eine Eigenschutzfunktion vom Stahl, denn er bildet eine Barriere gegen Rost. Ist die Klinge erstmal mit der Patina bedeckt, hat Rost kaum noch eine Chance, sofern Sie das Messer halbwegs pfleglich behandeln. Pflegen Sie Ihre Messer bei längerer Lagerung und/oder hoher Luftfeuchtigkeit mit einem Tropfen lebensmittelechtem Klingen-Öl, welches Sie kostengünstig in unserem Shop erwerben können.

3. Was bedeutet "rostfrei" ?

Zuerst einmal: Kein Stahl ist "rostfrei". Die korrekte Bezeichnung sollte eher "rost-träge" lauten. Da sich die Menschen aber an das Wort"rostfrei" gewöhnt haben, werden wir es hier auch in unseren Erklärungen verwenden. Ein Stahl wird mit mindestens 13% Chrom legiert, um ihn gegen Säuren und Feuchtigkeit zu schützen. (positiv für z.B. Outdoormesser, Obstmesser(Fruchtsäure) oder Tauchermesser(Salzwasser))

Chrom bildet im Stahl relativ große Karbide, die sich quasi als "Klumpen" im Stahl ablagern.

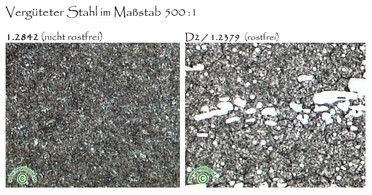

Mit freundlicher Unterstützung von www.metallograph.de haben wir im folgenden Bild zwei "Stahl-Klassiker" gegenübergestellt. Man sieht hier recht deutlich die Chromkarbide und die deutlich gröbere Struktur im rostfreien Stahl auf der rechten Seite. (Links = Carbonstahl / rechts = Rostfrei)

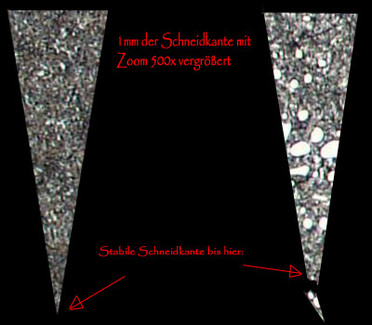

Stark vereinfacht ausgedrückt kann man sagen: Wenn man die Schneide sehr dünn ausschleift, dann ist bei dem rostfreien Stahl nicht genügend Seitenhalt für die Karbide vorhanden und die Schneide bricht bei Belastung schneller aus. Hierbei reden wir nicht von Ausbrüchen die man mit dem Auge erkennen kann, sondern wir sprechen von wenigen 1/100 mm!

Im Allgemeinen haben nicht rosftreie Stähle also eine stabilere Schneidkante als Chromstähle.

Um diesen Effekt entgegenzuwirken, sollte man die Schneide nicht ganz so dünn ausschleifen und je nach Belastung der Schneide den Winkel beim Schleifen etwas vergrößern.

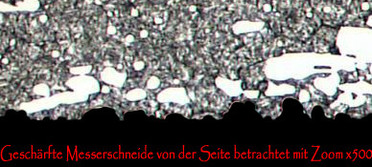

Betrachtet man die mikrometerfeinen Ausbrüche an der Schneide von der Seite, so erkennt man den Vorteil einer rostfreien Messerklinge. Rostfreie Messerstähle funktionieren im Allgemeinen als mikrofeine Säge. Quasi ein superfeiner Wellenschliff! Zwar verfliegt die Rasierschärfe recht schnell, aber sie schneiden dafür sehr lange auf einer ordentlichen "Gebrauchsschärfe" im Zugschnitt.

Ausserdem ist das Messer unempfindlich gegen Rost und sieht auch nach langem Gebrauch noch aus wie frisch poliert.

Alternativ zu den beschriebenen "Karbidmonstern" mit Sägeeffekt gibt es noch rostfreie Messerstähle, bei denen man so wenig Kohlenstoff hinzulegiert, dass die Karbide nicht genügend "Futter" haben um zu wachsen. (Chromkarbide benötigen Kohlenstoff um sich zu bilden) Somit hat man am Ende einen rostfreien Stahl, der keinen wirklichen Sägeeffekt hat, aber dafür sehr dünn ausgeschliffen werden kann fast wie ein nicht rostfreier Carbonstahl. Hierbei ist aber der Nachteil, dass der Stahl aufgrund des mangelnden Kohlenstoffs nicht so hart wird und die Schnitthaltigkeit oft zu Wünschen übrig lässt.

Was ist nun besser?

- Kommt es bei einem Messer auf höchste Schärfe an (z.B. Rasiermesser, Sushi-Messer, Filetiermesser) und/oder auf eine sehr stabile Schneidkante (z.B. Jagdmesser, Haumesser, Schwerter, Äxte)... dann sollte man zu einem nicht rostfreien Stahl greifen.

- Wenn es bei dem Messer auf langes Durchhaltevermögen auf mittlerem Niveau ankommt (z.B. Arbeitsmesser, Rescue-Knife, Outdoormesser) oder auf die Rostfreiheit (Outdoor, Küche, Jagd, usw) sollte man eher zu einem rostfreien Stahl greifen mit genügend Chrom und Kohlenstoff, dass er den gewünschten Sägeeffekt und eine Härte von mindestens 58 HRC erreicht.

Was ist Damaszenerstahl und warum sind die Messer so teuer?

Ein handgeschmiedetes Messer aus Damaszenerstahl zu schmieden ist neben einem Schwert aus Damast eines der beeindruckendsten handwerklichen Meisterstücke die man aus Stahl herstellen kann. Ein Damastmesser vereint verschiedene Stähle und somit auch verschiedene Stahleigenschaften zu einer ganz neuen Legierung, die im Damast perfekt auf den Anwendungszweck abgestimmt werden kann.

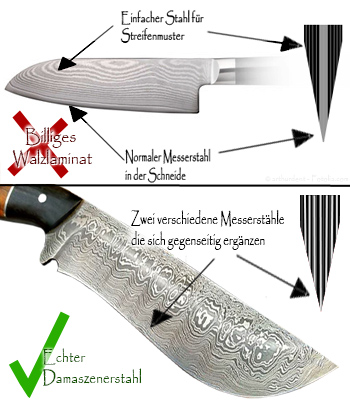

Leider wird der Begriff "Damaszenerstahl" heutzutage von der Industrie oft für vergleichsweise minderwertige Schweissverbund-Laminate missbraucht um die spezielle Damastoptik zu erzeugen. Dieser Damaststahl wird allerdings in großen Walzwerken hergestellt und hat nur wenig mit dem echten Damaszenerstahl zu tun. Bei den Walzlaminaten findet man in der Schneide eine Lage normalen Klingenstahl (oft rostfrei) der für die Schnittaufgaben genauso gut/schlecht geeignet ist wie ein Messer ohne Streifen. Auf diese Schneidlage wurden in dem Walzwerk weitere Stahlschichten aufgebracht um eine Art "Streifentapete" zu erhalten. Diese hat allerdings keinerlei Einfluss auf die Schnittqualiät der mittleren Schneidlage, da diese Lagen ja auch nicht in der Schneidlage vorhanden sind.

Die bessere Alternative für industriellen Damast wird in sogenannten "Monsterpaketen" hergestellt. Hierbei Wird ein Damastpaket von mehreren hundert Kg. unter Schutzgas erwärmt und anschließend unter einer riesigen Presse verschweißt. Danach wird das riesige Damastpaket in kleinere Stücke zersägt und maschinell zu Blechen geformt um daraus Messer zu machen. Dieser Damast nennt sich "Superclean" oder "Ultraclean". Der Vorteil sind perfekte Schweissverbindungen und eine maximale Reinheit und Fehlerfreiheit.

Bei diesem Damast muss man allerdings bedenken, dass die Messer und deren Anwendungszwecke immer auf das identische Material zurückgreifen und es nicht möglich ist den Damast speziell auf die Wünsche des Kunden und die Funktion des Messers von Hand zu schmieden. Dieses Verfahren ist in etwa damit vergleichbar einen handgenähten Anzug vom Schneider nur in einer Einheitsgröße anzubieten. Wenn er passt, dann ist es ein Schnäppchen, aber wenn nicht, dann muss man sich halt einen schneidern lassen.

Fragwürdig ist auch, dass man sich oft nicht sicher sein kann, wie gut die Qualität der verwendeten Stähle vom Ausgangsmaterial war. Aus diesem Grund empfehlen wir ganz genau darauf zu achten woher der Damast kommt und wer ihn hergestellt hat!

In unserem Shop finden Sie einen hervorragenden "Ultraclean-Damast" 100% made in Germany. Die Qualität von diesem Material ist über jeden Zweifel erhaben.

Gibt es Qualitätsunterschiede bei Damaszenerstahl?

Es gibt RIESIGE Unterschiede in der Qualität, auch wenn er ähnlich aussieht!

Nur wenn alle 5 Kriterien erfüllt sind, ist ein Damastmesser seinen Preis wert.

1. Die Stähle im Damast sollten sich in ihren Eigenschaften ergänzen und zum Anwendungszweck passen. Gerade bei preisgünstigen Damaststählen aus dem Ausland wird ganz dreist gelogen, denn es werden oft irgendwelche Stähle als hochwertige Komponenten wie 1095 oder 15N20 ausgegeben. Das Resultat können Sie hier in einem Youtubevideo von uns sehen: https://youtu.be/xpiopTZRwyA

Unser Tip: Finger weg von Billigdamast!

2. Die Anordnung der Stähle im Damaststahl und das Mischungsverhältnis sollte entsprechend den Anforderungen gewählt werden. Auch die Lagenanzahl sollte mindestens 150 Lagen betragen. Wir empfehlen pro mm Materialstärke 50-100 Lagen

3. Das Stahlgefüge muss durch eine präzise Wärmebehandlung optimal eingestellt werden. Bei der Herstellung von Damastzenerstahl wird der Stahl auf über 1.200°C erhitzt. Hierdurch leidet das Stahlgefüge enorm und der Stahl wird grobkörnig und spröde. Nur wenn der Gefügezustand fachmännisch korrigiert und wieder verfeinert wurde, wird das spätere Messer auch lange scharf bleiben und Ihnen Freude bereiten. Damastkauf ist Vertrauenssache in die Fähigkeiten des Herstellers. Andernfalls kaufen Sie die Katze im Sack.

4. Kleine Schweissfehler im Damaszenerstahl können vorkommen, jedoch sollten diese sehr klein sein und bestenfalls kaum sichtbar sein. Auf keinen Fall dürfen große Fehler einfach mit dem Schweißgerät ausgebessert werden, denn diese Bereiche werden später nicht hart. Achten Sie auf große Flecken die das Muster unterbrechen. Sie werden erstaunt sein wie häufig man so etwas zu sehen bekommt.

5. Das Härten und Anlassen von der fertigen Klinge sollte von einem erfahrenen Damastschmied durchgeführt werden. Nur wenn man das Material genau kennt, kann man optimale Ergebnisse erzielen. Lohnhärtereien sind oft nicht in der Lage die Klinge als Einzelstück zu härten und entfesseln nicht die Leistungsfähigkeit die in gutem Damaszenerstahl schlummert.

Ein wirklich handgeschmiedetes Messer aus Damaszenerstahl...

(also ein Unikat) unterscheidet sich leider im Namen nicht von industriellen Produkten, da die Begriffe Damastmesser, Damaszenerstahl, Damast, Damascus Steel, Damaststahl, Damastmesser, Damaszener, usw. nicht geschützt sind und sie jeder auslegen kann wie er meint.

Für uns bei Schmiedeglut bedeutet die Herstellung von einem handgeschmiedeten Damastmesser, dass es auch wirklich in Handarbeit geschmiedet wurde. Es bedeutet bei der Herstellung von dem Damaszenerstahl mehrere Stunden Arbeit, für die viel Fachwissen erforderlich ist... Muskelkater und verschwitzte Arbeitskleidung am Abend... viel Liebe zum Detail und eine Portion Kreativität um jedes Messer einzigartig zu machen. Bei unseren Messern greifen wir auf die bestmöglichen Ausgangsmaterialien und ausgewählte Klingenstähle zurück, vereinen diese zu einer optimalen Legierung und schmieden daraus eine einzigartige Klinge bei der jedes Messer ein Unikat ist. Diese kombinieren wir nach individuellen Kundenwünschen mit erlesenen Griffmaterialien zu einem hervorragenden Messer. Alle Messer von Schmiedeglut vereinen knallharte Funktion, Fakten und Qualität mit künstlerischen Kombinationsmöglichkeiten zu Ihrem individuellen Wunschmesser.

Woraus besteht handgeschmiedeter Damast?

Die Herstellung von Damast ist die Königsdisziplin der Schmiedekunst!

Unser Damast besteht aus zwei (oder mehr) Stählen, die unterschiedliche Eigenschaften aufweisen.

Der eine ist sehr hart und verschleissfest, der andere zäh und flexibel. Somit ist es möglich eine Klinge zu erschaffen, welche bei sehr hoher Schärfe, Schnitthaltigkeit und Härte gleichzeitig flexibel und Belastbar ist. Das typische Damast-Muster entsteht durch das mehrfache "Falten" und "Feuerschweissen" der Stähle, wodurch die Klinge oft aus mehreren hundert Lagen Stahl besteht!

Unser Damast besteht aus hochwertigsten Carbon-Stählen und wird je nach Messer und Funktion auf ca. 60-64 HRC (Rockwell) gehärtet.

Welche Stähle verarbeiten Sie?

Grundsätzlich sind wir offen für jeden Stahl, sofern er in der Praxis eine Verbesserung mit sich bringt!

Aus diesem Grund schmieden wir für jede Klinge einen eigenen Damaszenerstahl, der perfekt auf den jeweiligen Anwendugszweck abgestimmt ist.

Um herausragende Ergebnisse zu erzielen, kombinieren wir folgende Stähle in unterschiedlichen "Mischungsverhältnissen".

Nachfolgend finden Sie einige Stähle die wir häufig verwenden.

1.2519

Ein hervorragender Klingenstahl (nicht rostfrei) für hohe Schnitthaltigkeit bei gleichzeitig hoher Schärfe.

Härte ca. 62-64 HRC Rockwell

Im Damast ist er als graues Element zu finden.

75Ni8 (15N20)

Dieser Stahl bringt eine ausgezeichnete Zähigkeit und Stabilität mit sich.

Härte ca. 60-61 HRC

Im Damast zeichnet er hellgrau.

1.2842

Guter "Allrounder" mit hoher Härte von 61-62 HRC

Im Damast zeichnet er schön schwarz.

1.2235

Federstahl mit verbesserter Schnitthaltigkeit

Härte ca. 62-64 HRC

Im Damast ist er als graues Element zu finden.

60N20 (Sonderlegierung)

Superreines Gefüge für extrem feine Schneiden bei gleichzeitig hoher Flexibilität! Ich nutze ihn für ausgewählte Klingen die extremen Belastungen standhalten müssen und/oder für sehr Kontraststarke Muster.

Härte ca. 60-62 HRC

Im Damast zeichnet dieser Stahl extrem hell.

1.2767

Etwas weniger hart bei gleichzeitig höherer Schnitthaltigkeit.

Härte ca. 54-56 HRC

Fast so hell wie der 60N20.

1.1274 - C100

Superfeiness Gefüge für extrem feine Schneiden. Unübertroffen für Rasiermesser oder Sushi-Messer!

Härte ca. 63HRC